From your idea and drawings to the first fully qualified part, SMK Mold has the engineering expertise to design a working mold, shoot the initial shots, optimize the parameters then provide First Article Inspection Reports. If required PPAP and CPK data will be provided.

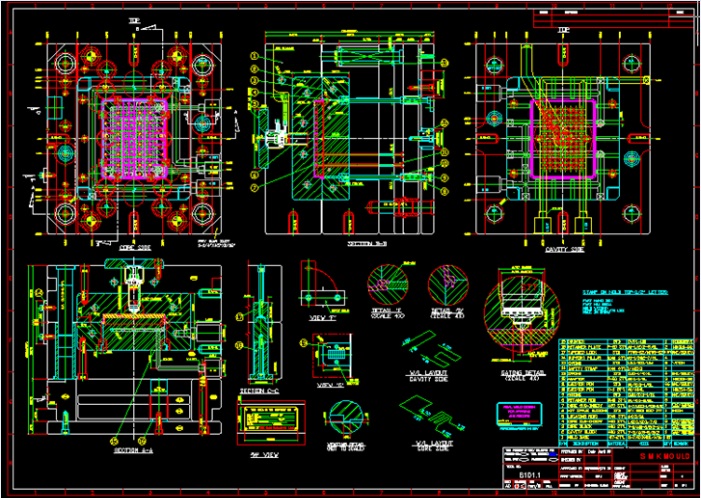

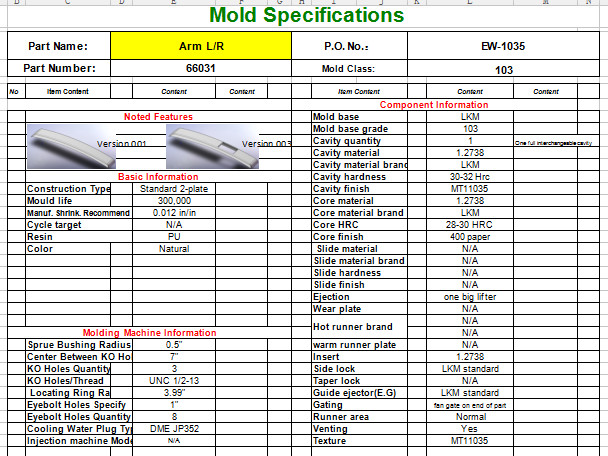

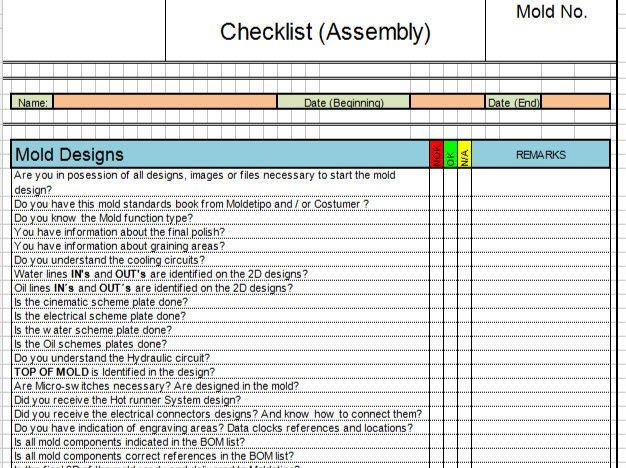

SMK Mould specializes in complete tool design for each tool procured. We have design teams available to support your needs. From a simple 2D drawing to a complete 3D data base we generate DFM, the flow analysis, potential ways to improve the final component and any risks associated...

Upon DFM and mould drawing approval, we begin the production of the tool and prepare for FOT (First Off Tool) which typically occurs within a few weeks. The FOT parts are provided to the customer to fit check and test the "real" component...

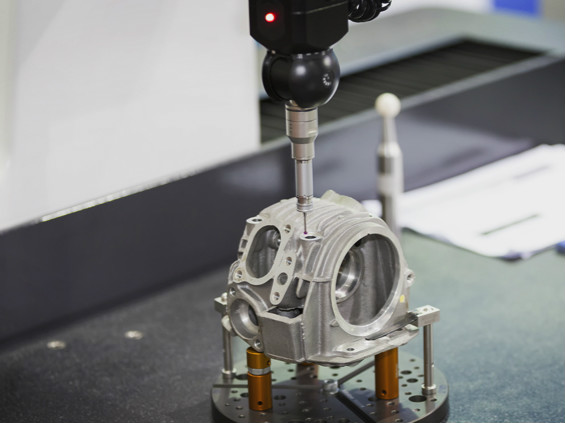

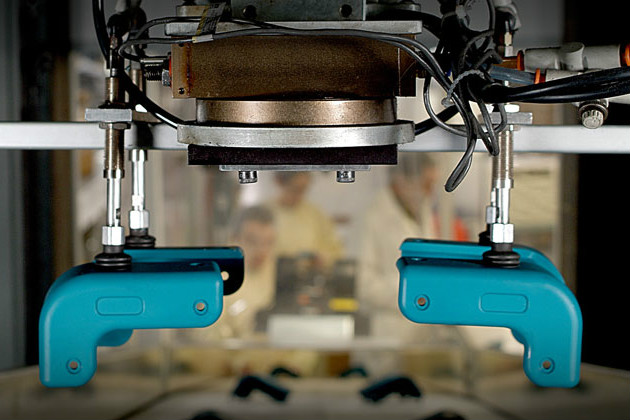

SMK Mould has good inspection system to insure the part and mould with high quality and meet customer requirement...

Copyrights © 2017-2020 All Rights Reserved SMK Mould Inc.,Ltd